My Industrial Design Journey at The Master Lock Company

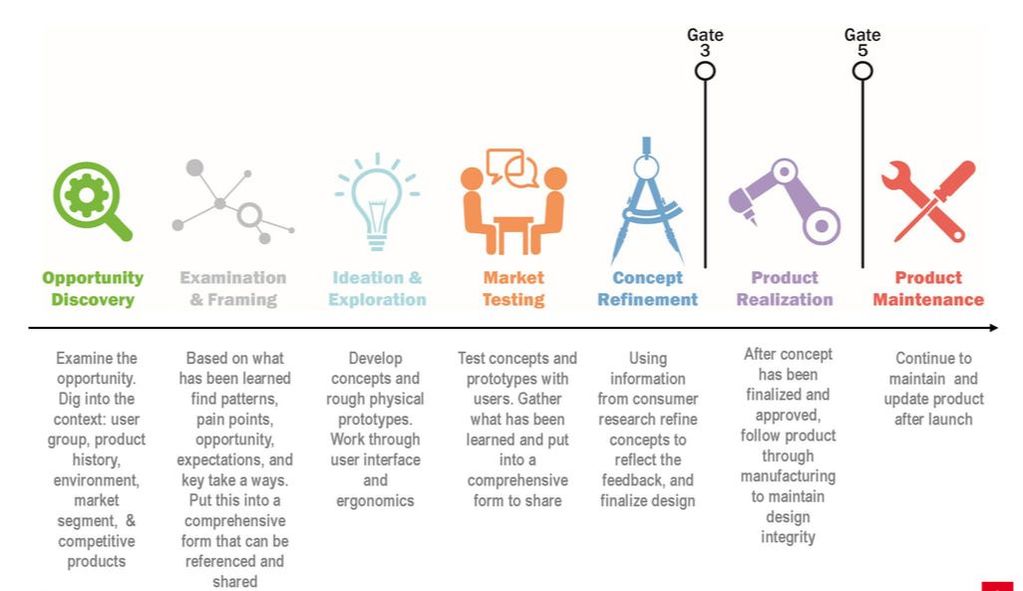

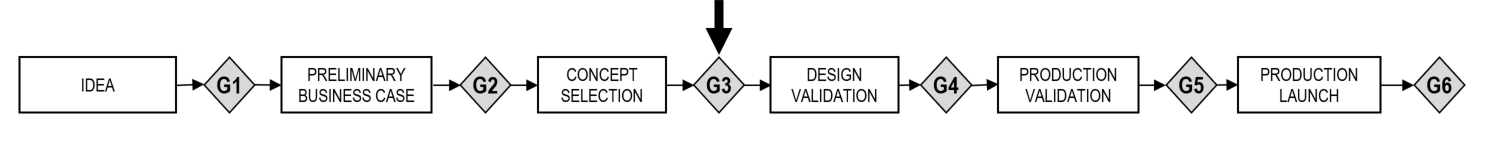

Back in 2008 when I started at The Master Lock Company I was just out of school. There was one other Industrial Designer who had also just finished school, and that was it. No one else within the company had any experience in design, or design leadership. At the time if you would have asked someone within the company what Industrial Design was, most would have said, “I have no clue,” or something along the lines of, “they choose the color of the product and refine some of the surfaces.” I have worked diligently over the last ten years to change this, having the privilege to build a design team from scratch. It has been an arduous but rewarding journey. I received no internal mentorship leading me in the right direction. I have had to forge my own path, learning how to navigate corporate structure, align myself with the right people, and influencing them to change and embrace their knowledge of Industrial Design. I have developed processes and changed our entire corporate approach to New Product Development. Successfully building upon a 95-year-old iconic American brand and bringing it into the 21st century with globally focused products and innovative technology to fit into the security needs of people today.

I am incredibly proud to say that if I ask a New Product Development team member what Industrial Design is today, they will tell you that Industrial Design is critical to the success of a new product. That it is essential to meet our consumer’s needs effectively, for usability, functionality, and aesthetics. Lastly, they would tell you, that our company would not be successful without it.

Changing a corporate culture did not happen overnight. It has taken hard work, perseverance, and courage. It has not always been easy, and I have made mistakes along the way, stumbled and fallen, but I continue to get back up, learn and refocus. Change equals opportunity, and learning to capitalize on that has helped me to make the design team what it is today. I am not afraid of change, instead I embrace it, always looking for innovative ways to improve and develop our products, brand, and culture.

Below I have outlined a few of my accomplishments and events that were critical to the development of the Industrial Design team at The Master Lock Company.